Haiti, January 2011. Environmentally friendly solar powered ovens are bringing hot food relief to hundreds of families in Haiti’s earthquake refugee camps. But even better, they are also helping to cut down on deforestation and carbon dioxide emissions. Jeremy Torr reports.

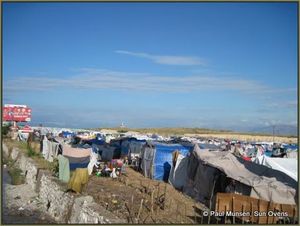

With hundreds of thousands of Haitians homeless and living in tent camps, living with the threat of disease from badly prepared food, the need for properly cooked food is desperate in the earthquake-ravaged country. Victims of the Haiti earthquake are still living in tents - so a hot meal means a lot, especially to the children.Although 11 months have elapsed since the earthquake, the needs of the local people are if anything greater than they were last January just after the earthquake. Hundreds of thousands of people remain in tent cities and a cholera outbreak has ripped through Haiti killing more than 1,800 people. Access to well-cooked, healthy food is a real problem.

Victims of the Haiti earthquake are still living in tents - so a hot meal means a lot, especially to the children.Although 11 months have elapsed since the earthquake, the needs of the local people are if anything greater than they were last January just after the earthquake. Hundreds of thousands of people remain in tent cities and a cholera outbreak has ripped through Haiti killing more than 1,800 people. Access to well-cooked, healthy food is a real problem.

Most of the cooking in the tent camps is done with locally-produced charcoal which adds deforestation to the already pressing problems of the devastated country. Additionally, the smoke produced by this basic method of cooking adds to health problems, giving rise to respiratory problems in mothers doing cooking - and their young children too.

One US company, Sun Ovens, is attempting to help by sending innovative solar-powered ovens to Haiti on a subsidised basis. The ovens have been developed and refined over many years to give the best results from simple sunlight – something that is still abundantly available for free in Haiti. Setting up and using the Sun Ovens is easy and can be done in any space there is access to sunlight.Built around a simple insulated box (the oven) with a heat-proof glass lid, the ovens use highly polished reflectors to bounce energy-packed sunlight into the cooking compartment. The whole oven can be packed down for transport and an adjustable stand makes it easy to aim at its power source, the sun. And the result, although maybe not as fast as a powered oven, is effective.

Setting up and using the Sun Ovens is easy and can be done in any space there is access to sunlight.Built around a simple insulated box (the oven) with a heat-proof glass lid, the ovens use highly polished reflectors to bounce energy-packed sunlight into the cooking compartment. The whole oven can be packed down for transport and an adjustable stand makes it easy to aim at its power source, the sun. And the result, although maybe not as fast as a powered oven, is effective.

According to Paul Munsen, president of Sun Ovens, the solar devices get pretty hot.

“The reflectors and insulated compartment mean we can get temperatures up to 190 degrees C. The other good thing is the insulation helps keep cooked food warm for longer,” he adds.

Part of the company’s policy is to help provide local work as well as cooking facilities. “We don’t want to just supply completed ovens from the US. If we do that we can get a few hundred in a container,” he explains. “If we ship the parts we can send thousands, and create work for local people to assemble them too.” The people of Hait may not have much in the way of material possessions - but they have plenty of sunshine.In the last 11 months several hundred small-sized cardboard Cookits, nearly 500 ovens and several Global village-sized ovens have been shipped to Haiti. Additional shipments are planned for later this year.

The people of Hait may not have much in the way of material possessions - but they have plenty of sunshine.In the last 11 months several hundred small-sized cardboard Cookits, nearly 500 ovens and several Global village-sized ovens have been shipped to Haiti. Additional shipments are planned for later this year.

The original Sun Oven design was developed in 1986 by Tom Burns, a retired restaurateur from Milwaukee, Wisconsin, who obviously knew a great deal about cooking. Additionally, his extensive international travel made him aware of the ever-growing problem of deforestation.

Burns took a simple concept that has been around for centuries (refecting the sun to keep things warm) and re-engineered it with up to date design and technology and materials to produce the Sun Oven.

Since 1986 thousands of the ovens have been shipped to more than 126 countries around the globe. “They have been sent to Ghana, Dominican Republic, Uganda, Haiti, South Africa and Nigeria,” says Munsen. “We have had lots of success in areas that traditionally use charcoal or wood for cooking.”

Assembly plants to make the ovens have been set up in a number of developing countries, both to reduce the cost of the ovens and to help local tradespeople. The ovens can be shipped in unassembled, or built locally from easily made parts, but the company prefers to build them on the spot. The advantage of the Sun Oven is that it costs nothing to run - but it also improves health in confined spaces.“Part of our policy is to empower local people to make and market our ovens,” says Munsen. “This gives local craftsmen the chance to help build the ovens and get new business.” Microfinace is often used to help would-be oven entrepreneurs to establish their business.

The advantage of the Sun Oven is that it costs nothing to run - but it also improves health in confined spaces.“Part of our policy is to empower local people to make and market our ovens,” says Munsen. “This gives local craftsmen the chance to help build the ovens and get new business.” Microfinace is often used to help would-be oven entrepreneurs to establish their business.

Back in Haiti the problems are still immense. Using Sun Oven to fill the gap between the emergency phase and the long-term development phase will undoubtedly help. But this need not be simply a stop-gap initiative.

According to Munsen, the annual wood used for cooking in developing countries is over 400kg per person per year. Using that as a benchmark, a family of six using a large sun oven for around three-quarters of their cooking needs would save 88 tons of CO2 emissions over the 20-year life of the oven.

Additionally, as forests disappear, the burden of finding cooking fuel for poor families falls increasingly upon women and girls in both urban and rural settings. In rural areas women often spend hours a day gathering wood, and often risk attacks and rape in the process.

And in poor urban areas over half the entire household income is often spent on purchasing cooking fuels. Solar powered ovens could help alleviate both these problems in many countries around the world.

Using Sun Ovens need not just be a simple and practical solution for the refugees in Haiti; it could help all of us benefit in the long run.

Want to help people in Haiti with a hot meal? Check out the donation button at SUN OVEN® website: www.sunoven.com.

Photos by Paul Munsen