Working the Web: Sustainable Tourism Online

Brightwater: 21st Century Wastewater

Imagine a sewage treatment facility where people get married, surrounded by acres of restored habitat with ponds and fish-friendly wetlands. It sounds far-fetched but it’s reality in Snohomish County, Washington. By Jared Green.

Brightwater is a modern sewage treatment facility that enhances the environment and increases quality of life for local communitiesWashington, 21 October 2015- Michael Popiwny is a visionary landscape architect who managed a $1 billion project for a wastewater treatment plant - one that successfully demonstrates how sewage can become an asset instead of a drain on communities and the environment.

Brightwater is a modern sewage treatment facility that enhances the environment and increases quality of life for local communitiesWashington, 21 October 2015- Michael Popiwny is a visionary landscape architect who managed a $1 billion project for a wastewater treatment plant - one that successfully demonstrates how sewage can become an asset instead of a drain on communities and the environment.

Popiwny says the key to success was an interdisciplinary management, design, and construction team that was highly responsive to community feedback and deeply sensitive to environmental concerns. And it's self funding; as new people are attracted to the quality of life in the area, they move in and pay a $4,000 – $8,000 sewer hook-up fee. “The fact that new people were paying for the system helped us to sell it to the community,” says Popiwny.

Massive machine

Meadows and wetlands trap and store clean rainwater which are then channelled into salmon migratory streams.Brightwater is a 114-acre site that started operations in 2011, and cleans sewage from around four million households. It has 20 km of underground pipes feeding sewage water to the plant from the surrounding wealthy residential area that are piped into the largest membrane bioreactor system in North America. This produces water that is 70% cleaner than conventional approaches, so it can be piped to a 200 metre-deep outfall pipe several kilometres out into the Puget sound. Excess solids are extracted and sold to local farms and orchards at very low cost.

Meadows and wetlands trap and store clean rainwater which are then channelled into salmon migratory streams.Brightwater is a 114-acre site that started operations in 2011, and cleans sewage from around four million households. It has 20 km of underground pipes feeding sewage water to the plant from the surrounding wealthy residential area that are piped into the largest membrane bioreactor system in North America. This produces water that is 70% cleaner than conventional approaches, so it can be piped to a 200 metre-deep outfall pipe several kilometres out into the Puget sound. Excess solids are extracted and sold to local farms and orchards at very low cost.

But Brightwater is more than a processing plant. It is a treatment facility, environmental education and community center, and ecological system rolled into one. Popiwny describes the design and construction process: “We had separate contracts for the engineering and design teams. We needed the strongest engineering team and the strongest landscape architecture team, and in the end we combined their efforts in the final design," he says.

As the processing facilities were dug out of the landscape, the excess soil was turned into “decorative, geometric landforms" that by being used locally took thousands of trucks off the highway and saved lots of carbon, says Popiwny.

The top end of Brightwater (that was once an auto garage) now features an elaborate system of forests, meadows, raingardens, wetlands, and ponds that hold and clean rainwater before directing it to the streams that salmon use.

Restored Ruins

Complex habitat restoration involved the use of 15 different rock types to construct stream corridorsThe process of restoring the habitat and turning into a publicly-accessible park was complex, involving stream and wetland biologists, who guided ecological decisions. The team used 15 different types of rocks to create two different stream corridors that empty into ponds where salmon rest on their uphill climb to the places where they spawn.

Complex habitat restoration involved the use of 15 different rock types to construct stream corridorsThe process of restoring the habitat and turning into a publicly-accessible park was complex, involving stream and wetland biologists, who guided ecological decisions. The team used 15 different types of rocks to create two different stream corridors that empty into ponds where salmon rest on their uphill climb to the places where they spawn.

To help restore the wetland, Popiwny and his team decided on a community outreach project. Kids from the area helped plant over 20,000 native willows to create community buy-in and grow a sense of greater investment in the success of the project. "We had about 4-6 busloads of kids from the surrounding area every week," says Popiwny.

The site also features an environmental education center, designed and built to LEED Platinum level that is often used for non-profit organization meetings and community meetings. It also houses an environmental education center, which features flexible classrooms for groups of all ages to enable hands-on learning about the water cycle.

The parkland, environmental education and community centers were all part of $149 million set aside by the local authorities as part of a “mitigation budget.” According to Popiwny, providing these facilities also helped promote the facility to local people - who might otherwise have objected to a conventional sewage treatment plant.

"Budgeting this upfront meant saving money over the long run," he says. But despite the community buy-in, the Brightwater project was sued by local sewer operators who argued the project “spent too much on mitigation!” Luckily, the State Supreme Court sided with Brightwater and dismissed the claims.

Checking culture

“But there need to be multiple checks as these projects can affect communities," says Popiwny. Indeed, he adds, locals benefited from the opposition as it pushed the designers towards a higher performance, even though it made it more expensive through the implementation of technical fail-safe systems. These include multiple, isolated ponds to separate acid or bases if there is an overflow or accident caused by an earthquake. All engineering pipes and systems are also designed to withstand high levels of seismic activity.

Recreational parks for the community to enjoy Its not all mechanics and engineering though. Spread throughout the site is public art, as part of the state’s cultural programme. "We realized that this place needed to be beautiful. We need it to look great as well as be very [functionally] designed," says Popiwny. The results are there to see.

Recreational parks for the community to enjoy Its not all mechanics and engineering though. Spread throughout the site is public art, as part of the state’s cultural programme. "We realized that this place needed to be beautiful. We need it to look great as well as be very [functionally] designed," says Popiwny. The results are there to see.

Nestled in an environmental wilderness, with some 70 acres of trails and parks open to the public, Brightwater has managed to become a welcoming place that has restored the ecological function of the landscape - as well as process 136 million litres of wastewater a day for 15 million local household users.

For more info on Brightwater go to: http://www.kingcounty.gov/environment/wtd.aspx

Managing Tilapia Farms Sustainably to Feed the Poor

Text and Photos by Henrylito D. Tacio

Davao City, 1 July 2014. After bangus (milkfish), tilapia is now the second most important fish in the Philippines. These days, tilapia fish cages are a common sight in almost all the major rivers and lakes in the country, including Laguna de Bay, Taal Lake, and Lake Sebu. It is very popular among Filipinos who cooked the fish in different ways, including fried, grilled, sinigang (a sour soup using tamarind, santol, guava or calamansi as a base) and paksiw (similar to sinigang only it uses vinegar).

It’s no wonder why tilapia has replaced galunggong as the poor man’s fish. Tilapia has provided many Filipinos, especially the lower income households, with access to cheap source of animal protein.

Dr. Rafael D. Guerrero III, an Academician of the National Academy of Science and Technology who popularized tilapia raising in the country, said the Philippines is “now one of leading producers of tilapia in the world today.”

This has been confirmed by Agriculture Secretary Proceso Alcala during the Fourth Tilapia Congress last year. “The Philippines,” he said, “has maintained its position among top tilapia producing countries, cornering eight percent of the total world production.”

Last year, the world tilapia production exceeded 4 million metric tons, according to Dr. Guerrero. The Philippines contributed more than 260,000 metric tons. “Tilapia is now second only to the carps as the world's most important farmed fish based on production,” he added.

The popularity of tilapia as a food fish has spread around the world. Aside from the Philippines, the other biggest producers in Asia are: China, Malaysia, Vietnam, Indonesia, Taiwan and Sri Lanka. In South America, the top producers are: Brazil, Costa Rica Ecuador and Peru. The United States is the biggest importer of tilapia while China leads as the biggest exporter.

If the Philippines has to maintain its edge, it has to increase its tilapia production in the coming years. But the industry has to solve some of the problems it currently faces: degradation of quality fingerlings due to inbreeding, insufficient supply of quality tilapia fry in far flung areas, high cost of farm inputs and poor quality feeds, lack of technology transfer initiatives at the grassroots level, and lack of value-added products.

As such, the Department of Science and Technology (DOST) thinks of doing interventions to boost capacity of tilapia production systems and enhance product competitiveness. Through its line agency, Philippine Council for Agriculture, Aquatic, and Natural Resources Research and Development (PCAARRD), it launched Strategic Science and Technology Plans (ISP) for tilapia.

PCAARRD, in its recently released annual report, said the ISP for tilapia aims “to produce better-performing breeds, specifically the red tilapia.” Through this program, a base population within red Nile tilapia family has been established.

“Two generations were produced and grown for selection,” the report said. In addition to red Nile tilapia, seven tilapia breeds were collected and crossbred.

As much as 90% of the tilapia cultured in the country is sex-reversed, Dr. Guerrero reported. “At least 50% of the tilapia produced in the United States, Canada, Israel, the Caribbean and Asia is sex-reversed,” he pointed out.

It was Dr. Guerrero himself who developed the sex reversal tilapia (SRT) technology. For his feat, he was awarded the IBM Science and Technology award by the IBM Philippines.

“Artificial sex reversal is considered the most effective, efficient and economical method for solving the major drawback of growing tilapias to market-size caused by unwanted reproduction,” Dr. Guerrero said.

“With mix-sex (male and female) stocks, the fish matures early and breeds frequently resulting in stunted growth due to overpopulation in ponds,” he added. “By growing all-male tilapia produced through hand-sexing (manual separation of sexes), hybridization (crossbreeding of two appropriate species) or sex reversal, the yield of large-sized tilapias is significantly increased by 30 percent to 50 percent because of the faster-growing males compared to females and the control of reproduction.”

The commercial tilapia sex reversal feed (SR Premix) is available from its exclusive manufacturer and distributor, Aquatic Biosystems. Interested individuals can write the owner at this email: aquabios@yahoo.com.

According to Dr. Guerrero, applying the sex reversal feed method with a success rate of at least 95 percent requires the production of the right age of the fry for treatment, preparation of the hormone feed or its procurement, and the proper application of the treatment.

In its annual report, PCAARRD said some of its researchers are currently doing experiments on using pine pollen as source of phytoandrogen (substance in plants that have similar effects to testosterone in animals) to promote sexual inversion.

Tilapia fry given the pine pollen reportedly showed comparable results to the use of synthetic hormone. “The pine pollen-treated males produced fry within 16 days post stocking, which means that the sex inversed females became functional males,” the report said.

To solve the high cost of feeds for tilapia, PCAARRD likewise conducted some studies on various feeds. Initial data on field trials showed positively that fry easily adapted to the feeds introduced.

According to the report, positive increase in terms of average body weight, length, and width of the fish were observed.

The data also showed that ingredients used in the feed formulations -- cassava meal, camote meal, copra meal, corn meal, rice bran, and golden apple snail -- were sufficient to meet the nutritional requirements of cultured tilapias.

This is good news for Filipinos. After all, fish provides more than half of the protein requirement of almost all Filipinos.

Industrial Emissions: Algae that Eat Pollution

Any system that cuts down industrial pollution is a bonus – but if the method can use natural organisms rather than chemicals or energy-intensive industrial processes, then that’s even better. By Jeremy Torr and ASLA’s Phil Stamper.

Philadelphia, United States, 21 October 2013. According to Taimur Burki, Global Green Building Program Manager for Intel Corporation, the possibility of using algae to cut industry pollutants is a real one. At a session at a recent conference he noted that during the certification of severa wafer fabrication plants for Intel, he was able to achieve LEED NC and LEED EBOM certification, even though the process at the plants involved highly complex chemical and water-intensive processes.

“We managed to achieve those while driving the world's largest semiconductor company to a 90% solid waste recycling goal - and improving the green building footprint via a multiplicity of efforts,” he said.

Intel's Brad Biddle is helping Intel to cut CO2Together with Joshua Wray, a graduate Research Assistant (PhD) at Arizona State University, Burki looked at the possibility of using algae as an industrial emissions control strategy. Their team analysed the results of an experiment between ASU and Intel to measure algae’s impact on the industrial sector.

Intel's Brad Biddle is helping Intel to cut CO2Together with Joshua Wray, a graduate Research Assistant (PhD) at Arizona State University, Burki looked at the possibility of using algae as an industrial emissions control strategy. Their team analysed the results of an experiment between ASU and Intel to measure algae’s impact on the industrial sector.

Wray, a self-professed algae farmer, has been involved in many bioremediation projects in the past that involved capturing nutrients from waste streams, but, in this case, the algae was intended to draw carbon and nitrogen from flue gases produced in an industrial process.

After identifying the many alternate uses of algae—biofuels, pharmaceuticals, even in food—researchers found that some strains are very adaptable. Picking and choosing the best strains for this experiment was incredibly important, says Wray. “With full development and implementation of this technology,  Many organizations are already using algae to treat sewageindustries could better manage their greenhouse gas emissions making it easier to meet ever-tightening air quality standards while making their operations more sustainable,” he said. The main problem is that only specific strands of algae will feed on carbon dioxide and help reduce emissions; identifying which ones is key to the success of the technology.

Many organizations are already using algae to treat sewageindustries could better manage their greenhouse gas emissions making it easier to meet ever-tightening air quality standards while making their operations more sustainable,” he said. The main problem is that only specific strands of algae will feed on carbon dioxide and help reduce emissions; identifying which ones is key to the success of the technology.

The Arizona desert, used as a test site, was perfect for many reasons, said Wray. The dry places offer a lot of sun (which is key to photosynthesis, and important part of the process), heat, access to wastewater and it is made up of non-arable land so does not displace any other valuable agricultural activities.

And at ASU, the number of world-renowned algae scientists is higher than normal – so the location virtually chose itself. ASU worked with Intel to erect flat panel bioreactors on the roof of one of their fabrication buildings to capture boiler emissions and convert the otherwise waste pollutants into biofuel. The reactors were filled with algae grown from ponds or other bioreactors. “CO2 and greenhouse gas emissions are newly regulated at many industrial sources. Control technologies for these gases are not readily available yet, so it is important to understand which technologies may be viable either currently or in the future,” said Tim Higgs, Corporate Environmental Engineer for Air Quality at Intel and another contributor to the project.

Higgs also noted that working with agencies in developing countries such as China to help them learn from their experiences how to implement pollution control and sustainability in their home countries. Researchers studied the roof-mounted bioreactors to see if they could grow algae, whether any CO2 was filtered out and if this process could be used to create clean-burning processes.

Intel’s project leader Brad Biddle said the outcome was already giving “some pretty exciting results” but admitted there is still much research to be done and many follow-up experiments on the system are required, but noted they had great success in growing algae and filtering carbon and nitrogen oxides out of the flue gas.

The ASU-Intel pilot is already growing algae from flue gas, the next step is to scale up the processThough the desert light and heat are best for the experimental work and for the algae farmers, similar work is going on at several other research establishments. In the US, Duke Energy and the University of Kentucky have a partnership that will soon start using algae to convert flue gas emissions into biofuel. And in India, the country’s largest generation utility has launched a project to use algae to minimise CO2 output from power generation plants.

The ASU-Intel pilot is already growing algae from flue gas, the next step is to scale up the processThough the desert light and heat are best for the experimental work and for the algae farmers, similar work is going on at several other research establishments. In the US, Duke Energy and the University of Kentucky have a partnership that will soon start using algae to convert flue gas emissions into biofuel. And in India, the country’s largest generation utility has launched a project to use algae to minimise CO2 output from power generation plants.

As Biddle says, it’s still a process that researchers are learning about every day, but its potential is outstanding. A key to sustainable building is to reduce carbon emissions, and if something as small and plentiful as microalgae can help bring plants to near-zero emissions, that’s exciting possibilities for the future. “The big question is scalability,” he admits, “but we found a really important answer to the question. Can you grow algae in a flue stack? And the answer is yes.”

Watch the pilot video of the project

Industrial Emissions: Algae that Eat Pollution

Any system that cuts down industrial pollution is a bonus – but if the method can use natural organisms rather than chemicals or energy-intensive industrial processes, then that’s even better. By Jeremy Torr and ASLA’s Phil Stamper.

Philadelphia, United States, 21 October 2013. According to Taimur Burki, Global Green Building Program Manager for Intel Corporation, the possibility of using algae to cut industry pollutants is a real one. At a session at the 2013 Greenbuild in Philadelphia, he noted that during the certification of severa wafer fabrication plants for Intel, he was able to achieve LEED NC and LEED EBOM certification, even though the process at the plants involved highly complex chemical and water-intensive processes.

“We managed to achieve those while driving the world's largest semiconductor company to a 90% solid waste recycling goal - and improving the green building footprint via a multiplicity of efforts,” he said.

Together with Joshua Wray, a graduate Research Assistant (PhD) at Arizona State University, Burki looked at the possibility of using algae as an industrial emissions control strategy. Their team analysed the results of an experiment between ASU and Intel to measure algae’s impact on the industrial sector.

Wray, a self-professed algae farmer, has been involved in many bioremediation projects in the past that involved capturing nutrients from waste streams, but, in this case, the algae was intended to draw carbon and nitrogen from flue gases produced in an industrial process.

After identifying the many alternate uses of algae—biofuels, pharmaceuticals, even in food—researchers found that some strains are very adaptable. Picking and choosing the best strains for this experiment was incredibly important, says Wray. “With full development and implementation of this technology, industries could better manage their greenhouse gas emissions making it easier to meet ever-tightening air quality standards while making their operations more sustainable,” he said. The main problem is that only specific strands of algae will feed on carbon dioxide and help reduce emissions; identifying which ones is key to the success of the technology.

The Arizona desert, used as a test site, was perfect for many reasons, said Wray. The dry places offer a lot of sun (which is key to photosynthesis, and important part of the process), heat, access to wastewater and it is made up of non-arable land so does not displace any other valuable agricultural activities.

And at ASU, the number of world-renowned algae scientists is higher than normal – so the location virtually chose itself. ASU worked with Intel to erect flat panel bioreactors on the roof of one of their fabrication buildings to capture boiler emissions and convert the otherwise waste pollutants into biofuel. The reactors were filled with algae grown from ponds or other bioreactors. “CO2 and greenhouse gas emissions are newly regulated at many industrial sources. Control technologies for these gases are not readily available yet, so it is important to understand which technologies may be viable either currently or in the future,” said Tim Higgs, Corporate Environmental Engineer for Air Quality at Intel and another contributor to the project.

Higgs also noted that working with agencies in developing countries such as China to help them learn from their experiences how to implement pollution control and sustainability in their home countries. Researchers studied the roof-mounted bioreactors to see if they could grow algae, whether any CO2 was filtered out and if this process could be used to create clean-burning processes.

Intel’s project leader Brad Biddle said the outcome was already giving “some pretty exciting results” but admitted there is still much research to be done and many follow-up experiments on the system are required, but noted they had great success in growing algae and filtering carbon and nitrogen oxides out of the flue gas.

Though the desert light and heat are best for the experimental work and for the algae farmers, similar work is going on at several other research establishments. In the US, Duke Energy and the University of Kentucky have a partnership that will soon start using algae to convert flue gas emissions into biofuel. And in India, the country’s largest generation utility has launched a project to use algae to minimise CO2 output from power generation plants.

As Biddle says, it’s still a process that researchers are learning about every day, but its potential is outstanding. A key to sustainable building is to reduce carbon emissions, and if something as small and plentiful as microalgae can help bring plants to near-zero emissions, that’s exciting possibilities for the future. “The big question is scalability,” he admits, “but we found a really important answer to the question. Can you grow algae in a flue stack? And the answer is yes.”

Smart Highways : Smarter than Smart Cars?

Next-generation solar cells: Graphene is the answer

Green Disc 2012: Sustainable Development Solutions for All

Singapore's Cleantech R&D in Energy & Water Gets More Funding

Text and photo by Mallika Naguran

12 July 2011, Singapore. Singapore's research and development (R&D) in clean technology has received two major funding boosts by the government recently. Chairman of Singapore Economic Development Board Leo Yip announced today at Clean Technology Investment World Asia 2011 that the National Research Foundation (NRF) has set aside an additional S$195 million for five years to nurture reseach and manpower capabilities within the clean energy industry.

Chairman of EDB Leo Yip: Cleantech a key sector for Singapore's economic growth

The new fund will help reach 2015 targets of S$1.7 billion of economic value-added and 7,000 skilled jobs. It will also build on existing strengths in solar energy while diversifying into new growth areas such as smart grids, green buildings, and carbon capture and utilisation.

Apart from supporting research in industry-oriented innovation, part of the fund will serve as competitive grants to solicit "bottom-up innovations", commercialize R&D results and develop postgraduate talent.

This allocation follows a week after Deputy Prime Minister Tharman Shanmugaratnam's announcement at the Singapore International Water Week 2011 of an additional S$140 million from NRF devoted to R&D in the water sector.

Singapore’s Four Ingredients

Singapore eyes the cleantech industry as a key sector for economic growth. “We believe that Singapore offers global cleantech companies a unique combination of four key ingredients, all in one place,” says Chairman Yip. “They are technology, markets, talent and capital.”

Technology

Cleantech research and innovation will be a growth driver, even with the extra S$195 million funds pumped into the clean energy sector. This will help strengthen solar energy research, plus stimulate new growth areas such as smart grids, green buildings, and carbon capture and utilization.

Solar Energy Research Institute of Singapore, home to 160 top researchers, is collaborating with Norway’s REC and China’s Trina Solar. SERIS is regarded as the top solar research institute in Asia, outside Japan. The Nanyang Environment & Water Research Institute (NEWRI) is a comprehensive and integrated research centre in water and environmental technologies, and has undertaken joint R&D projects with Toray and Sembcorp.

Although Singapore has no wind market, the island city has built up capabilities for this sector in material sciences and control systems. This, according to Yip, has helped attract global R&D centres from leading wind companies such as Vestas and Gamesa.

Market

What Cleantech Park would look like in 2030

The island nation is ready as a test-bed for green solutions. For instance, its water agency PUB gives companies access to its infrastructure for the testing advanced water technologies. Singapore’s slew of international environmental events serve as springboards for companies to access global markets.

Singapore's Cleantech Park will be the region's first eco-business park that will allow companies showase systems-level cleantech solutions.

Singapore will be participating in the International Cleantech Network, a leading network of cleantech clusters around the world.

Talent

Initiatives are being implemented to develop cleantech manpower capabilities of overseas and local talents at across all levels. Companies such as Vestas, GE and Siemens found talent availability rather attractive in setting up innovation facilities in Singapore.

Capital

A growing base of venture capitalists, private equity firms, banks and corporate investors in Singapore provide the funds needed for companies intending to be based in Asia. Singapore Economic Development Board Investment (EDBI) places its interest in innovative companies that wish to grow in Asia through the lion city.

In fact the EDBI has invested in home-grown tidal energy turbine developer Atlantis Resources Corporation and Contour Energy Systems, A US-based next-generation battery technology development company.

www.terrapinn.com/cleantechasia

Liberia Fights Illegal Logging with Barcodes

Macau International Environmental Protection Exhibition 2011

Last year (2010) saw attendees from 48 countries at MIECF

Last year (2010) saw attendees from 48 countries at MIECF

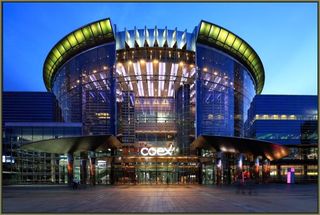

For the fourth consecutive year, Macau will host the Macao International Environmental Protection Exhibition and Forum (MIECF) from 31st March to 2nd April 2011. The expo will promote Macao´s role as an environmental protection platform between the Pan-Pearl River Delta and other countries of the world, with the key theme being “Green Opportunities – Low Carbon Urban Development”, advocating “Green Cities, Smart Technology, Sustainable Growth”. The event covers major areas in the green industry, including solar (photovoltaic and thermal), bio-energy, hybrid energy systems, electric cars and hybrid vehicles, charging stations, battery and storage solutions, building technology, facilities management, smart grid, waste disposal, water conservation, air pollution control, noise control, project finance and consulting. Last year, MIECF attracted over 5900 representatives of organizations from Mainland China and 47 other regions and countries.

Venue: Macau, SOR, China

Date: 31st March to 2nd April 2011

Website: www.macaomiecf.com.

Macau International Environmental Protection Exhibition.

For the fourth consecutive year, Macau will host the Macao International Environmental Protection Exhibition and Forum (MIECF) from 31st March to 2nd April 2011. The expo will promote Macao´s role as an environmental protection platform between the Pan-Pearl River Delta and other countries of the world, with the key theme being “Green Opportunities – Low Carbon Urban Development”, advocating “Green Cities, Smart Technology, Sustainable Growth”. The event covers major areas in the green industry, including solar (photovoltaic and thermal), bio-energy, hybrid energy systems, electric cars and hybrid vehicles, charging stations, battery and storage solutions, building technology, facilities management, smart grid, waste disposal, water conservation, air pollution control, noise control, project finance and consulting. Last year, MIECF attracted over 5900 representatives of organizations from Mainland China and 47 other regions and countries.

Venue: Macau, SOR, China

Date: 31st March to 2nd April 2011

Website: www.macaomiecf.com.